We have already discuss about fuse. As we know, fuse is required for the system to protect it from different system fault like short circuit fault, over-load on system. Here we are going to describe about fuse types that is used earlier and now popular also so that we can choose best for our system. Here we will discussed about Fuse Types || Description of all fuse types. Mainly, we will focus on rewireable fuse/semi-enclosed fuse (also known as kitkat), cartridge fuse, drop out fuse, MCCB. Let's describe about their details description to know them easily. The fuse types are as follows:-

Fuse Types

Rewireable fuses/Semi-enclosed fuse

This fuse is mostly used in house wiring and small current circuits, also known as semi-enclosed. Sometimes it is also known as kit-kat type fuse. It consists of a porcelain base carrying the fixed contacts to which the incoming and outgoing live or phase wires are connected by strands of wires which will melt when high amount of current is flow i.e. at overload condition and short circuit condition. The fuse wires can be made of lead, tinned copper, aluminum or an alloy of tin lead. Generally, the amount of current that lead to melt the wires is about twice the rated current.

Standard ratings of this type of fuses are 6, 16, 32, 63 and 100 A.

Advantages:

- Easy to remove or replace without any danger of coming into contact with a live wire.

- Used for low and medium voltage

- Rupturing current is less or small

- Negligible replacement cost

Disadvantages:

- Unreliable operation

- No-current limiting feature

- Lack of discrimination

- Small time lag

- Slow speed of operation

- Risk of flame and fire

Cartridge Fuse

Advantages:

- Simple and easy installation

- High rupturing capacity

- Low cost to compared to circuit breakers

- High reliability

- Non- deterioration

Disadvantages:

- Over heating of adjacent contact

- Replacement required after each operation

Drop-out fuse

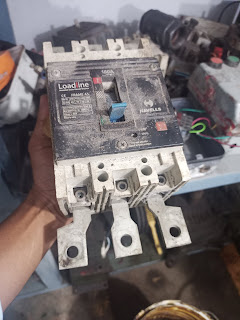

MCCB

MCCB stand for Molded case circuit breaker. For a electrical system, there need a protection system which will helps to protect the system in faulty cases such as short circuit condition, overhead condition etc. For a medium and large system in low voltage distribution, it is required for their protection. Here we will discuss about MCCB (Molded case circuit breakers) || What is MCCB?

MCCB definition

Molded case circuit breakers are circuit protection device for low voltage distribution systems. Generally, they will protect the loads in a system against both overloads and short circuits condition. Depending on the load current, we choose the best MCCB as requirement. There is current sensitive device as well as temperature sensitive device so that in short circuit case, if high amount of current is flow beyond its limit, it will trip and also in overload condition, if temperature is exceed beyond its limits then it will trip the circuit. In this way it work and help to protect the circuit, system, device or equipment from damage. Hence it is much more important in electrical system.

MCCBs are composed of five main components. They are:-

a) Frame: The frame is also known as the molded case, which provides an insulated housing to all the circuit breaker components in a MCCB.

b) Operating mechanism: This mechanism handles the opening and closing of the contacts so that supply will pass or cut as requirement. The opening and closing of the contact is independent of movement of handle i.e. fast or slow movement of handle. When circuit is tripped, the handle will be at mid position. At normal operating condition, the handle will be at up position and down position at off condition.

c) Arc extinguisher: An arc is obtained when a circuit breaker interrupts a current flow. The arc extinguishers will confine and divide the arc so that the arc will be easily extinguish.

d) Contacts: These are used to closed or open the circuit at normal or abnormal condition.

e) Trip unit: The trip unit is used to trip the contacts as the operating mechanism in the event of a short circuit or a preset value of overload current. The protection can be done by combining a temperature sensitive device with a current sensitive electromagnetic device, and both of them will operate mechanically on the trip mechanism. For short circuit protection, electromechanical trip circuit breakers have adjustable magnetic elements and for overload protection, electromechanical trip circuit breakers contain thermal trip elements. Breakers that use a combined of magnetic elements and thermal elements are often called thermo magnetic breakers.

No comments:

Post a Comment

----Please share your opinion with us-----